The materials to be processed vary in cost depending on the weight and size of the material. As for board materials, for acrylics, 1100mm x 1300mm of fixed length, 910mm x 1820mm of subrock board, and 1000mm x 2000mm of meter board are commonly used at O-M, but there are also 1200mm x 1800mm of shiroku board, 1200mm x 2400mm of shihachi board, and so on.

We also have engineering plastics and super engineering plastics 500mm x 1000mm, 1000mm x 1000mm, etc. Expensive materials can be cut into appropriate sizes, called “free cutting. Bars are usually available in 1000L (1m) and 2000L (2m), but more expensive materials such as super engineering plastics are also available in 300L and 500L. Bars can also be free-cut.

Processing fees also vary greatly depending on the ease of processing the material.

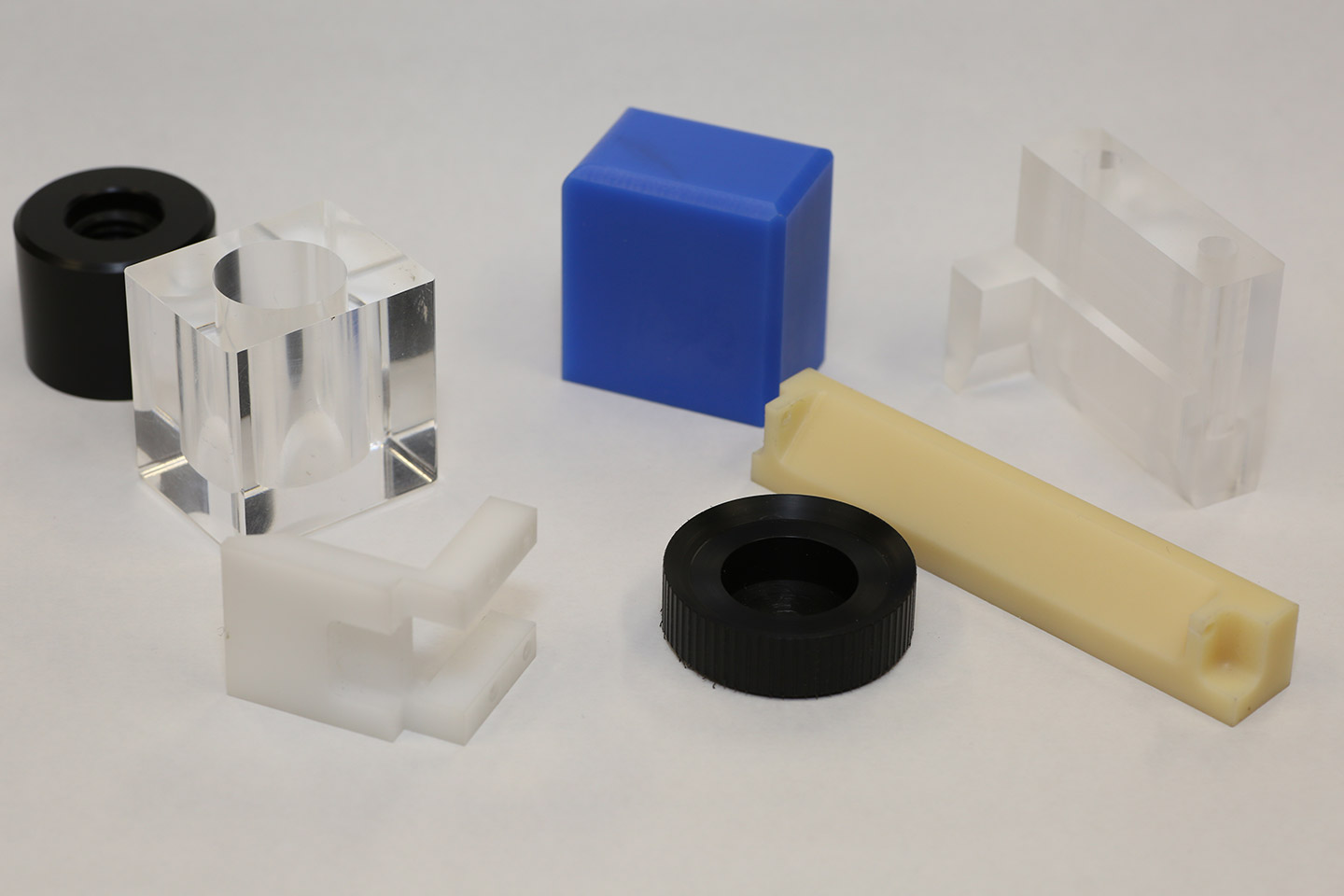

Among the types of plastics, material and plastic processing costs may vary depending on the type of material, with some materials being inexpensive and others being expensive.

General-purpose plastics < engineering plastics < thermosetting resins < super engineering plastics

Processing cost

General-purpose plastics < engineering plastics < thermosetting resins = < super engineering plastics

This is a rough estimate, but we hope you can use it as a reference.

We have all types of plastics in stock, including general-purpose, engineering plastic, super engineering plastic, and thermosetting plastic.