material

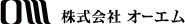

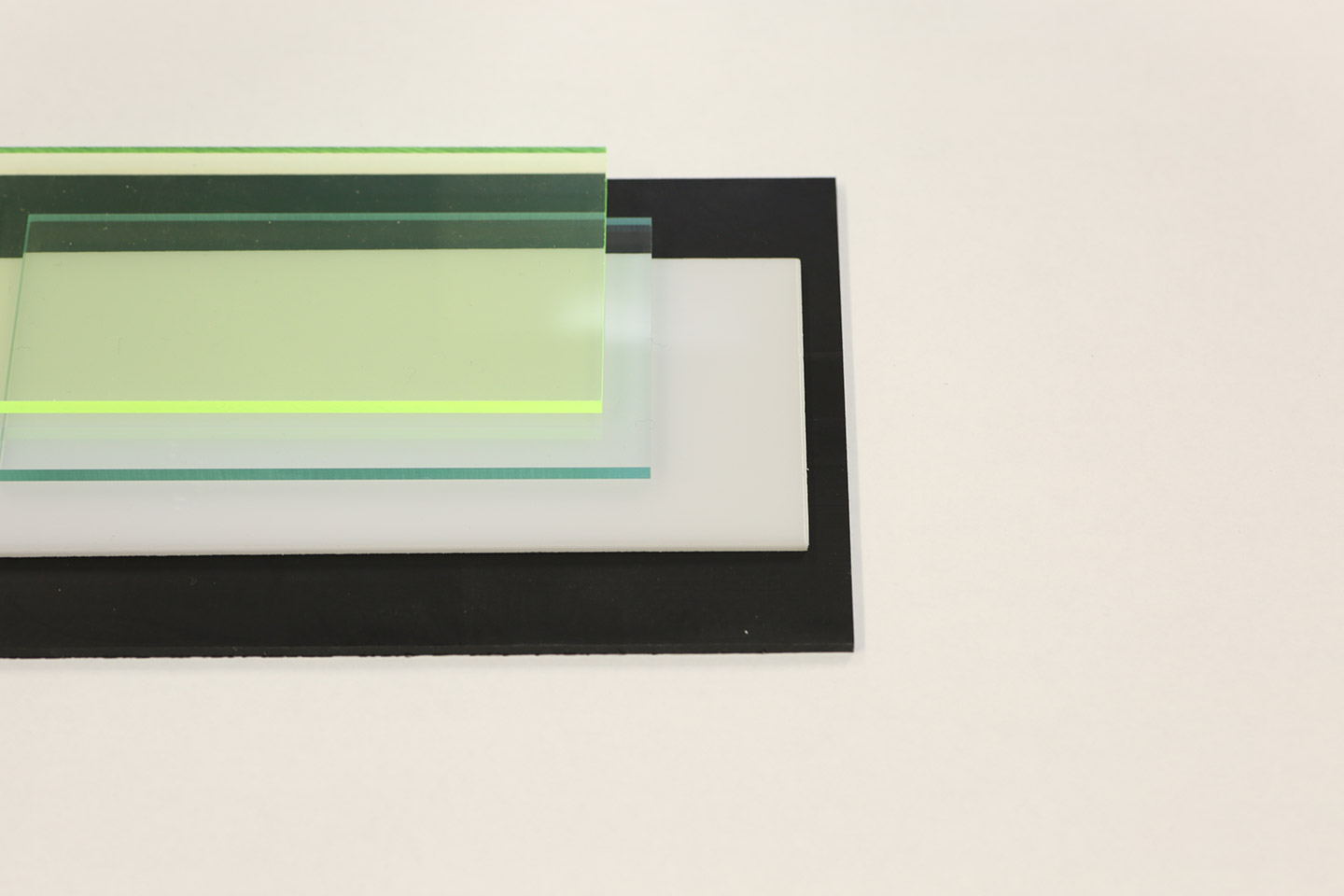

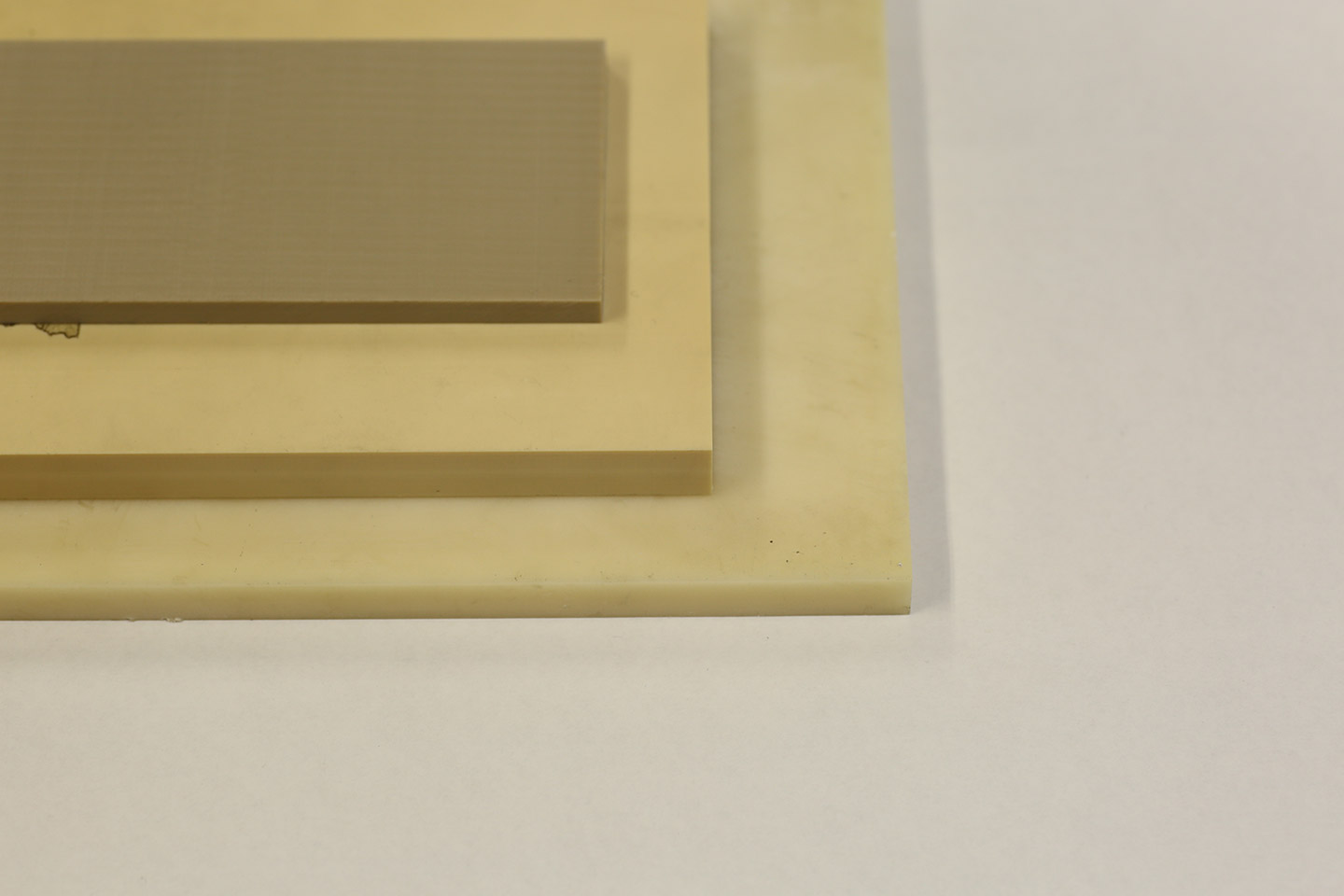

We perform precision cutting (machining) of all materials called resins (plastics).

Resins used for industrial parts can be mainly divided into thermoplastic and thermosetting resins, and within thermoplastic resins, they can also be divided into general-purpose plastics, engineering plastics, and super engineering plastics.

Each material has a wide range of choices in terms of temperature used, sliding properties, lightness, price, etc., and it is often very difficult to choose the right material for a wide range of applications.

Here, we will explain the characteristics (functions, uses, etc.) of each resin (plastic) in each of the categories described in the material selection section.